|

|

Normal Manganin 47 Precision Alloys Metal Copper Resistance For Wound Resistors

|

Product Details:

Payment & Shipping Terms:

|

| Resistivity(μΩ.cm):: | 8.44 | Electrical Resistivity At 20℃ (Ωmm2/m):: | 0.47 |

|---|---|---|---|

| EMF Vs Cu(μV/℃ )(0~100℃ ): | 1 | Melting Point (℃):: | 960 |

| Tensile Strength: | 390Mpa | Elongation: | 15% |

| Highlight: | nickel iron alloy,low expansion alloys |

||

Normal Manganin 47(Precision Resistance Alloy)

(Common Name:Normal Manganin,Normal Manganin 47,CuMn12Ni2 )

Normal Manganina 47 is a copper-manganese-nickel alloy (CuMnNi alloy) for use at room temperature. The alloy is characterized by very low thermal electromotive force (emf) compared to copper.

Normal Manganina 47 is typically used for the manufacturing of resistance standards, precision wire wound resistors, potentiometers, shunts and other electrical and electronic components.

Normal Manganin 47 widely used for precision resistors with the highest requirements, the resistors should be carefully stabilised and the application temperature should not exceed +60 °C. Exceeding the maximum working temperature in air may result in a resistance drift generated by oxidizing. Thus, the long-term stability can be affected negatively. As a result, the resistivity as well as the temperature coefficient of the electric resistance may slightly change.

It is also used as low cost replacement material for silver solder for hard metal mounting.The alloy's low emf vs. copper makes it ideal for use in electrical circuits, especially D.C., where a spurious thermal emf could cause malfunctioning of electronic equipment. Due to the low operating temperature, the temperature coefficient of resistance is controlled to be low over a range of 15 to 35°C .

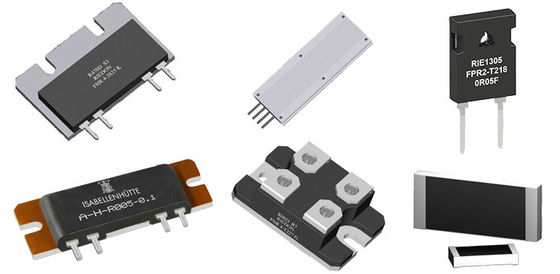

Precision resistors

Normal composition%

| Nickel | 2~3 | Manganese | 11~13 |

| Copper | Bal. |

Typical Mechanical properties(1.0mm)

| Yield strength | Tensile Strength | Elongation |

| Mpa | Mpa | % |

| 180 | 390 | 15 |

Typical Physical properties

| Density (g/cm3) | 8.44 |

| Electrical resistivity at 20℃ (Ωmm2/m) | 0.47 |

| Temperature factor of resistivity(20℃~600℃)X10-5/℃ | -3~20 |

| Conductivity coefficient at 20℃ (WmK) | 40 |

| EMF vs Cu(μV/℃ )(0~100℃ ) | 1 |

| Coefficient of thermal expansion | |

| Temperature | Thermal Expansion x10-6/K |

| 20 ℃- 400℃ | 18 |

| Specific heat capacity | |

| Temperature | 20℃ |

| J/gK | 0.41 |

| Melting point (℃) | 960 |

| Element working temperature in air (℃) | 5~45 |

| Magnetic properties | non-magnetic |

Corrosion resistance performance

| Alloys | Working In atmosphere at 20℃ | Working at max temperature 200℃ | |||||

|

Air and oxygen contain gases |

gases with Nitrogen |

gases with sulfur oxidability |

gases with sulfur reductibility |

carburization | |||

| Manganin 47 | good | good | good | good | bad | good | |

Style of supply

| Alloys Name | Type | Dimension | ||

| Manganin 47W | Wire | D=0.03mm~8mm | ||

| Manganin 47R | Ribbon | W=0.4~40 | T=0.03~2.9mm | |

| Manganin 47S | Strip | W=8~200mm | T=0.1~3.0 | |

| Manganin 47F | Foil | W=6~120mm | T=0.003~0.1 | |

| Manganin 47B | Bar | Dia=8~100mm | L=50~1000 | |

Contact Person: Mr. Qiu

Tel: +8613795230939

-

3J53 Precision Permanent Magnetic Alloy Similar to Ni Span C

-

Invar36 FeNi36 Precision Alloy Capillary Pipe Used in Medicine Industry

-

Top Quality Ready Stock of Kovar Tube / Pipe 4J29 / 29HK Tube

-

Expansion Fe Ni Co Alloy Wire Ni33Co17 For Sealing And Matching Ceramics

-

Vacuum Furnace Nickel Based Alloys For Glass - To - Metal Seal Vacuum Switch Tube

-

Constant Elastic Alloy 0.125mmx25mm 3J53 Strip for Spring