|

|

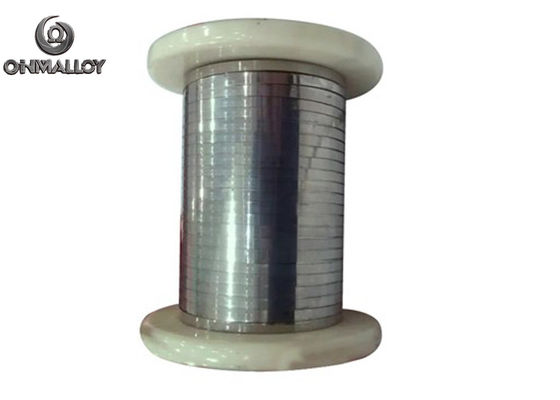

Resistance Heating CuNi19 NC025 Copper Nickel Alloy

|

Product Details:

Payment & Shipping Terms:

|

| Name: | CuNi19 NC025 Nickel Alloy Rod Strip Wire Valves Precision Resistance Parts Material | Material: | CuNi19(CN025) |

|---|---|---|---|

| Resistivity: | 0.25(at 20℃ (Ωmm2/m)) | Temperature Factor Of Resistivity(20℃~600℃)X10-5/℃: | <25 |

| EMF Vs Cu(μV/℃ )(0~100℃ ): | -32 | Supply State: | Wire/Strip/Rod |

| Max Working Temperature(℃): | 300 | Warranty: | 3 Years |

| Highlight: | NC025 Copper Nickel Alloy,CuNi19 Copper Nickel Alloy,Resistance Heating Copper Based Alloys |

||

CuNi19 NC025 Nickel Alloy Rod Strip Wire Valves Precision Resistance Parts Material

OhmAlloy025 (Resistance heating wire and resistance wire)

(Common Name:CuNi19,NC25)

OhmAlloy025 is a copper-nickel alloy (Cu81Ni19 alloy) with low resistivity for use at temperatures up to 300°C.

The ductility of copper-nickel alloy is very good, so it can be used in shipbuilding and petrochemical industry. Some electrical appliances and meters also use the ductility of copper-nickel alloys to manufacture parts. Copper-nickel alloys are mostly used in industrial production. Some valves and some precision resistance parts will be made of copper-nickel alloys.

Copper Nickel Alloy Production Standard(GB/T1234-95)

| Performance Brand | NC020 CuNi14 |

NC025 CuNi19 |

NC030 CuNi23 |

NC035 CuNi30 |

NC040 CuNi34 |

NC050 CuNi44 |

|

| Main Chemical Content% | Ni | 14.2 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | |

| Element Max Working Temperature℃ | 300 | 300 | 300 | 350 | 350 | 400 | |

| Density g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Resistivity Ωmm2/m, at 20℃ | 0.20±5% | 0.25±5% | 0.30±5% | 0.35±5% | 0.40±5% | 0.49±5% | |

|

Temperature factor of resistivity 10-5/℃(200-600℃) |

<38 | <25 | <16 | <10 | -0 | <-6 | |

| Melting Point ℃ | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Tensile Strength MPa | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| Enlogation%(>1.0) | ≥25 | ≥25 | ≥25 | ≥25 | ≥25 | ≥25 | |

| EMF VS Copper V/℃(0-100℃) |

-28 | -32 | -34 | -37 | -39 | -43 | |

| Specific heat capacity j/gk(20℃) | 0.38 | 0.38 | 0.38 | 0.39 | 0.40 | 0.41 | |

| Conductivity coefficient w/mk at20℃ | 48 | 38 | 33 | 27 | 25 | 23 | |

| Organizational attribute | Austenitic | Austenitic | Austenitic | Austenitic | Austenitic | Austenitic | |

| Magnetic | None-Magnetic | None-Magnetic | None-Magnetic | None-Magnetic | None-Magnetic | None-Magnetic | |

Style of supply

| Alloys Name | Type | Dimension | ||

| OhmAlloy025W | Wire | D=0.06mm~8mm | ||

| OhmAlloy025R | Ribbon | W=0.4~40 | T=0.05~2.9mm | |

| OhmAlloy025S | Strip | W=8~200mm | T=0.1~3.0 | |

| OhmAlloy025F | Foil | W=6~120mm | T=0.005~0.1 | |

| OhmAlloy025B | Bar | Dia=8~100mm | L=50~1000 | |

CuNi19 NC025 Copper Nickel Alloy Application

![]()

![]()

Contact Person: Mr. Qiu

Tel: +8613795230939

-

Manganin Strip Copper Based Alloys

-

MYFE-4/200 Polyimide Film Wrapped Insulated Copper Round Wire

-

Nickel Silver Strip / CuNi18Zn20 / C75200 / CW409J / NS106 For Decoration

-

CuNi40 Constantan Copper Based Alloys 25% Elongation High Resistance Wire

-

Low Voltage Copper Alloys Constantan Ribbon / Flat Wire 8.9 g / cm3 Density

-

0.05-2.0mm CuNi10 Strip | Stable Resistivity | Instrumentation Resistors | Low Temperature Coefficient | ROHS