|

|

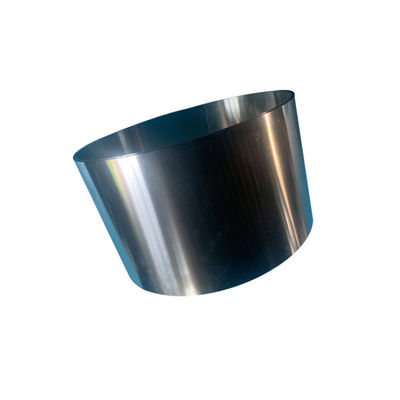

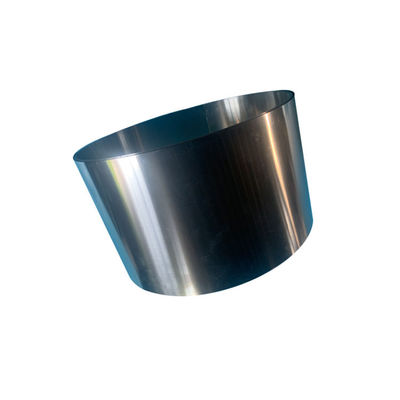

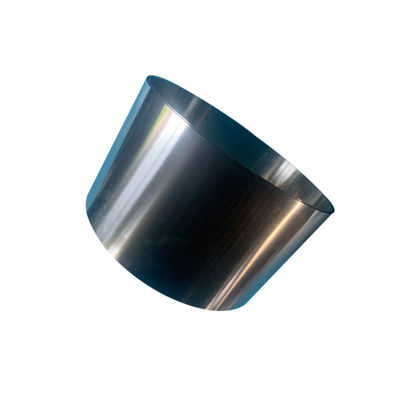

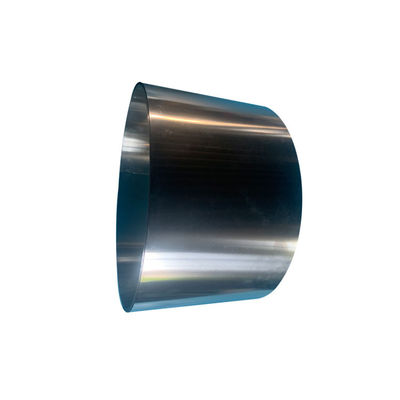

Thickness 0.4mm Vacodil 36 Low Expansion Alloys For Creep Gauges

|

|

Product Details:

Payment & Shipping Terms:

|

| Material: | FeNi | Chemical: | Fe64% Ni36% |

|---|---|---|---|

| Density: | 8.1g/cm3 | Surface: | Bright &smooth |

| Highlight: | Vacodil 36 Low Expansion Alloys,Thickness 0.4mm Low Expansion Alloys,Creep Gauges Low Expansion Alloys |

||

Invar Standard coil strip Thickness 0.4mm Vacodil36 strip

OhmAlloy-4J36 (Expansion alloy)

(Common Name: Invar, FeNi36, Invar Standard, Vacodil36)

OhmAlloy-4J36 (Invar), also known generically as FeNi36 (64FeNi in the US), is a nickel–iron alloy notable for its uniquely low coefficient of thermal expansion (CTE or α).

Name INVAR comes from the unchanged word, refer to its relative lack of expansion or contraction with temperature changes.

It was invented by the Swiss physicist Charles éduardguillaume in 1896. He received 1920 Nobel Physics Award in 1920, which is the discovery that improves scientific instruments.

OhmAlloy-4J36 (Invar) is used where high dimensional stability is required, such as precision instruments, clocks, seismic creep gauges, television shadow-mask frames, valves in motors, and antimagnetic watches. In land surveying, when first-order (high-precision) elevation leveling is to be performed, the Level staff (leveling rod) used is made of Invar, instead of wood, fiberglass, or other metals. Invar struts were used in some pistons to limit their thermal expansion inside their cylinders.

![]()

Normal composition%

| Ni | 35~37.0 | Fe | Bal. | Co | - | Si | ≤0.3 |

| Mo | - | Cu | - | Cr | - | Mn | 0.2~0.6 |

| C | ≤0.05 | P | ≤0.02 | S | ≤0.02 |

Typical Physical properties

| Density (g/cm3) | 8.1 |

| Electrical resistivity at 20℃(Ωmm2/m) | 0.78 |

| Temperature factor of resistivity(20℃~200℃)X10-6/℃ | 3.7~3.9 |

| Thermal conductivity, λ/ W/(m*℃) | 11 |

| Curie point Tc/ ℃ | 230 |

| Elastic Modulus, E/ Gpa | 144 |

Coefficient of expansion

| θ/℃ | α1/10-6℃-1 | θ/℃ | α1/10-6℃-1 |

| 20~-60 | 1.8 | 20~250 | 3.6 |

| 20~-40 | 1.8 | 20~300 | 5.2 |

| 20~-20 | 1.6 | 20~350 | 6.5 |

| 20~-0 | 1.6 | 20~400 | 7.8 |

| 20~50 | 1.1 | 20~450 | 8.9 |

| 20~100 | 1.4 | 20~500 | 9.7 |

| 20~150 | 1.9 | 20~550 | 10.4 |

| 20~200 | 2.5 | 20~600 | 11.0 |

Typical Mechanical properties

| Tensile Strength | Elongation |

| Mpa | % |

| 641 | 14 |

| 689 | 9 |

| 731 | 8 |

Temperature factor of resistivity

| Temperature range, ℃ | 20~50 | 20~100 | 20~200 | 20~300 | 20~400 |

| aR/ 103 *℃ | 1.8 | 1.7 | 1.4 | 1.2 | 1.0 |

| The heat treatment process | |

| Annealing for stress relief | Heated to 530~550℃ and hold 1~2 h. Cold down |

| Annealing | In order to eliminate hardening, which be bring out in cold-rolled, cold drawing process. Annealing needs heated to 830~880℃ in vacuum,hold 30 min. |

| The stabilization process |

|

| Precautions |

|

Style of supply

| Alloys Name | Type | Dimension | |

| OhmAlloy-4J36 | Wire | D= 0.1~8mm | |

| OhmAlloy-4J36 | Strip | W= 5~250mm | T= 0.1mm |

| OhmAlloy-4J36 | Foil | W= 10~100mm | T= 0.01~0.1 |

| OhmAlloy-4J36 | Bar | Dia= 8~100mm | L= 50~1000 |

![]()

FAQ

1. What's the minimum quantity customer can order?

If we have your size in stock, we can provide any quantity you want.

If we do not have, for spool wire, we can produce 1 spool, about 2-3kg. For coil wire, 25kg.

2. How can you pay for small sample amount?

We have account, wire transfer for sample amount also ok.

3. Customer do not have express account. How will us arrange the delivery for sample order?

Just need to provide your address information, we will check the express cost, you can arrange the express cost together with sample value.

4. What's our payment terms?

We can accept LC T/T payment terms, it also depending on delivery and total amount. Let's talk more in details after getting your detailed requirements.

5. Do you provide free samples?

If you want several meters and we have stock of your size, we can provide, customer need to bear the International express cost.

6. What's our working time?

We will give you reply through email/phone Online contact tool within 24 hours. No matter working day or holidays.

Contact Person: Mr. Qiu

Tel: +8613795230939

-

Invar Fe-Ni36 4J36 Low Expansion Iron Nickel Alloy 1.2 ppm°C Anti Corrosion

-

4J29 Kovar FeNi29Co17 Glass Sealing Low Expansion Alloys

-

Kovar Low Expansion Alloys 4J29 Strip Glass - To - Metal Seal For Light Bulbs

-

Near-Zero CTE Invar 4J36 Plate (UNS K93600)Precision Metrology and Cryogenic Applications

-

Alloy 42 FeNi42 Sealing Strip for Ceramic-to-Metal Glass Sealing

-

Kovar 4J29 Sealing Rod Precision Polished for Hermetic Feedthroughs