|

|

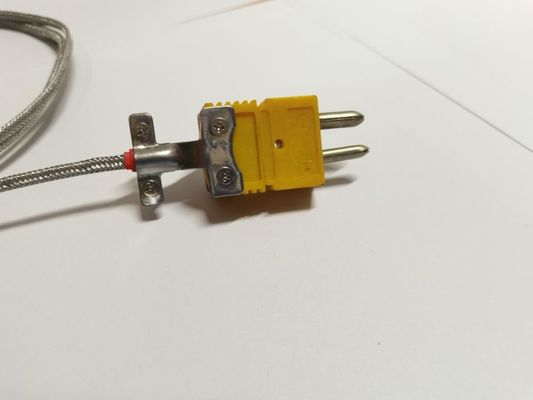

Compensation Thermocouple Type K Connector GH3030 Mineral Insulated

|

Product Details:

Payment & Shipping Terms:

|

| Product Name: | Mineral Insulated Thermocouple Type K | Type: | Type K |

|---|---|---|---|

| Max Working Temperature: | 1250℃ | Function: | High Temperature Testing |

| Uage: | Industrial Usage | Feature: | Portable And Fast Responding |

| Sheath Material: | GH3030 | ||

| Highlight: | SS304L Compensation Thermocouple Type K Connector,GH3030 Mineral Insulated Thermocouple Connector,Extension Mineral Insulated Thermocouple Connecto |

||

High Temperature GH3030 Mineral Insulated Thermocouple Type K Standard Connector

For Mineral insulated (MI) thermocouples, the basic parts are measuring element, insulation, protecting sheath. At most situation, MI thermocouples matched with flexible connector to add bending possibilities and compensation cables to improve the measure accuracy.

![]()

Armor Style Thermocouple Structure

- For the measuring wire, there are several common used type: Type K N E T J

![]()

2. Insulation Material: MgO(≥96%), Al2O3(≥99%)

3. Outer Sheath Material:

- 304L & 316L SS: + 700°C

- 310 (25/20) SS : + 1100°C

- Inconel 600 : + 1150°C

- GH3030 & GH3039: 1200°C

4. Mineral Insulated Parts Standards

![]()

|

Wire Diameter(D) And Tolerance |

Sheath Thickness(S) Mini Value |

Wire Diameter(C) Mini Value |

Insulation Thickness(I) Mini Value |

| 0.5±0.025 | 0.05 | 0.08 | 0.04 |

| 1.0±0.025 | 0.10 | 0.15 | 0.08 |

| 1.5±0.025 | 0.15 | 0.23 | 0.12 |

| 2.0±0.025 | 0.20 | 0.30 | 0.16 |

| 3.0±0.030 | 0.30 | 0.45 | 0.24 |

| 4.5±0.045 | 0.45 | 0.68 | 0.36 |

| 6.0±0.060 | 0.60 | 0.90 | 0.48 |

| 8.0±0.080 | 0.80 | 1.20 | 0.64 |

5. Connector:usually this part made by spring to increase bending possibilities.

6. Extension Cable:when chose the compensation/ Extension type, it should in line with the thermocouple index

In actual temperature measurement, usually there are long measuring distance with the measuring device, a thermocouple compensation wire is generated to compensate the temperature difference caused by the temperature change between the measuring device and the thermocouple connecting piece.

The compensation cable has the following advantages: improving thermocouple temperature measurement line physical properties and mechanical properties; improving the measurement line flexibility and making the connection convenient by using multi-strand core or small-diameter compensation wire; easy to shield external interference; reducing measuring lines cost.

Thermocouple Cable Grade

A:Extension Grade Cable

Whose wire composition is totally as the same as the thermocouple wire, remarked by the letter“X”after the thermocouple symbol number, such as“KX”“JX”“TX”

B:Compensation Grade Cable

Whose wire composition is different from the thermocouple wire, but its wire electromotive force (EMF) value is the same as thermocouple wire only at 0-100℃ or 0-200℃. It remarked by the letter“C”after the thermocouple symbol number, such as“KC”“JC”“TC”

| Thermocouple Type | Alloy Code | Nominal Chemical Composition(%) | Recommend Measuring Temperature | |||||||

| Cu | Ni | Cr | Fe | Si | Al | Mn | Mg | |||

| Type K | KP(Chromel) | 90 | 10 | 0-1200℃ | ||||||

| KN(Alumel) | 97 | 1-2 | 1-1.5 | 0.5-1.5 | ||||||

| Type T | TP(Copper) | 100 | -200-400℃ | |||||||

| TN(Constantan) | 55 | 45 | ||||||||

| Type J | JP(Iron) | 100 | 0~750℃ | |||||||

| JN(Constantan) | 55 | 45 | ||||||||

| Type E | EP(Chromel) | 90 | 10 | 0~900℃ | ||||||

| EN(Constantan) | 55 | 45 | ||||||||

| Type N | NP(NiCrSi) | 83-85 | 13.7-14.7 | 1.2-1.6 | <0.01 | 0-1200℃ | ||||

| NN(NiSiMg) | 93-96 | <0.02 | 4.2-4.6 | 0.5-1.5 | ||||||

Contact Person: Mr. Qiu

Tel: +8613795230939

-

Chromel Alumel Pin Thermometer Plug

-

High Temperature Screw Type K Thermocouple compensation wire/cable

-

Type RTD 7 X 24 AWG Thermocouple Cable PTFE Jacket With Stainless Steel Shield

-

High Temperature NiCr / NiAl Thermocouple Extension Wire 1.3mm X 2 AWG 16 Type K

-

+Chromel / -Alumel Conductor Extension Cable Type K With Vitreous Silica Insulation

-

High-Temperature K-Class Cable | 2*0.6mm Twisted Pair | ANSI MC96.1 | -270°C to 1372°C