|

|

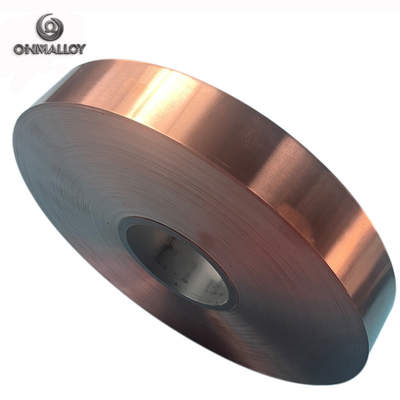

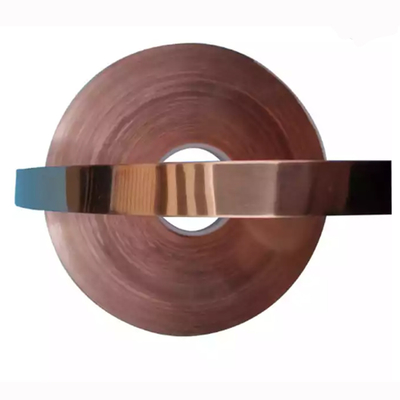

TD02 Half Hard Beryllium Copper Strips For Electronic Components

|

Product Details:

Payment & Shipping Terms:

|

| Thickness: | 0.254mm | Width: | 8.2mm |

|---|---|---|---|

| Status: | Bright And Half Hard (TD02/TD04) | MOQ: | 20KGS |

| Application: | Relays Stamping Parts And Switches | Ex-works: | 29.8USD/KG |

| Highlight: | Electronic Components Beryllium Copper Strips,TD02 Beryllium Copper Strips,Copper Based Alloys Strip Foil |

||

Copper beryllium strips C17200 for relays stamping parts and switches

Product brief introduction:

Beryllium cooper strip is widely used in producing all kinds of micromotor’s brush, switch, relay, cell phone battery, spring,connector, attemperator’s leaf spring which with high strength, high elasticity, high hardness and high wearing feature.

Chemical Composition:

Be: 1.85-2.10%

Co+Ni: 0.20% Min.

Co+Ni+Fe: 0.60% Max.

Cu: Balance

Note: Copper plus additions equal 99.5% minimum.

Features:

1. Strength: by age-hardening, can reach up to 1500N/mm2 tensile strength, so it be used as elastic material which can tolerate high bending stress.

2. Electrical conductivity: According to different alloys, specification, about 20-70% IASC (international annealed copper standard) can be used as high density voltaic elastic material.

3. Machinability: Before age hardening, the material can be complicated formed processing.

4. Fatigue Strength: Have excellent anti-fatigue properties(Can be operate repeatedly), so be widely used in long-life and high-reliability accessories.

5. Heat resisting property: Can keep small Stress relaxation rate in the high temperature condition, so can be used under a large temperature range.

6. Corrosion resistance: In range of all copper alloy, it has better corrosion resistance than Copper-Nickel Alloy,scarcely initiate corrosion by environmental implication.

Beryllium copper strip Mechanical Properties:

| Symbol or Brands | Chemical Composition | Temper | Tensile Strength (N/mm2) | Elongation (%) | Endurance | Vickers Hardness (HV) | Electric Conductivity (%IACS) |

| C1720 | Be:1.8-2.0 Ni+Co≥0.20 Ni+Co+Fe≤0.6 Cu+Be+Co+Fe ≥99.5 | Before age-hardening | |||||

| O | 410-540 | ≥35 | - | 90-160 | ≥17 | ||

| 1/4H | 510-620 | ≥10 | - | 45-220 | ≥16 | ||

| 1/2H | 590-695 | ≥5 | - | 180-240 | ≥15 | ||

| H | 685-835 | ≥2 | - | 210-270 | ≥15 | ||

| After age-hardening | |||||||

| OT | 1100-1380 | ≥3 | ≥960 | 325-400 | ≥22 | ||

| 1/4HT | 1180-1400 | ≥2 | ≥1030 | 350-430 | |||

| 1/2HT | 1240-1440 | ≥2 | ≥1100 | 360-440 | |||

| HT | 1270-1480 | ≥1 | ≥1140 | 380-450 | |||

| Spread (Standard) | |||||||

| OM | 685-885 | ≥18 | ≥480 | 220-270 | ≥17 | ||

| 1/4HM | 735-930 | ≥10 | ≥550 | 235-285 | |||

| 1/2HM | 815-1010 | ≥8 | ≥650 | 260-310 | |||

| HM | 910-1110 | ≥6 | ≥750 | 295-345 | |||

| XHM | 1100-1290 | ≥2 | ≥930 | 340-390 | |||

| XMHS | 1210-1400 | ≥2 | ≥1030 |

360-410 |

|||

Usage:

Casting beryllium bronze: (Cu-2Be-0.5Co-0.3Si, Cu-2.6Be-0.5Co-0.3Si, Cu-0.5Be-2.5Co, etc.) For explosion-proof tools, various molds (inner inserts for plastic injection molding dies, integral cavities for blow molds, automotive molds), bearings, bushings, bushings, gears and various electrodes

Processing beryllium bronze: (Cu-2Be-0.3Ni, Cu-1.9Be-0.3Ni-0.2Ti) is mainly used as a variety of advanced elastic components, especially requiring good conductivity, corrosion resistance, wear resistance, cold resistance, various no magnetic components, used as a large number of bellows, diaphragms, bellows, micro switches, etc.

Technical Specification

|

Density |

Hardness after Quenching | Tensile Strength | Yield Strength (0.2%) | Elastic Modulus |

Conductivity |

Thermal Conductivity at 20℃ |

| g/cm | HRC | MPa | MPa | GPa | IACS | w/m.k |

| 8.3 | ≥36-42 | ≥1000 | 1035 | 128 | 18% | 105 |

Grade and temper for C17200 CuBe2 Beryllium copper strip

Grade: C17200, C172, CDA172, QBe2, CuBe2, CB101

Temper: O(M), 1/4H(Y4), 1/2H(Y2), H(Y), HH(T)

Characteristic of C17200 CuBe2 Beryllium copper strip

• High Strength

• Good Formability

• Good corrosion resistance

• Easy welding and soldering

• Fatigue Resistant

Contact Person: Berry

Tel: +8615356123952

-

Manganin Strip Copper Based Alloys

-

MYFE-4/200 Polyimide Film Wrapped Insulated Copper Round Wire

-

Nickel Silver Strip / CuNi18Zn20 / C75200 / CW409J / NS106 For Decoration

-

CuNi40 Constantan Copper Based Alloys 25% Elongation High Resistance Wire

-

Low Voltage Copper Alloys Constantan Ribbon / Flat Wire 8.9 g / cm3 Density

-

0.3mmx4mm T2 C11000 R-Cu58 C101 Pure Copper Foil Soft Strip C1100 for Mobile Phone