|

|

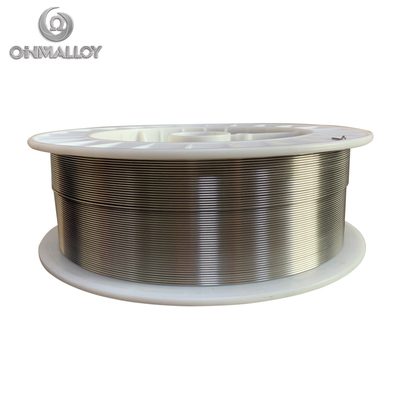

NiAl20 Thermal Spray Wire For Arc Spray Bonding Layer

|

Product Details:

Payment & Shipping Terms:

|

| Material: | NiAl20 | Diameter: | 2.0mm |

|---|---|---|---|

| Package: | 15kg/spool | Application: | Bond Coat, Dimensional Restoration |

| Spraying Way: | Arc Spraying | Typical Hardness: | HRB 75 |

| Bond Strength: | 9100 Psi | Deposit Efficiency: | 70% |

| Highlight: | NiAl20 Thermal Spray Wire,2.0mm Arc Spray Wire,Arc Bonding Layer Thermal Spray Wire |

||

NiAl20 wire thermal Spray Wire for Arc spray boning layer

PRODUCT OVERVIEW

Nickel based alloy wire

Thermal spraying techniques are coating processes in which melted (or heated) materials are sprayed onto a surface.The "feedstock" (coating precursor) is heated by electrical (plasma or arc) or chemical means (combustion flame).Thermal spraying can provide thick coatings (approx. thickness range is 20 micrometers to several mm, depending on the process and feedstock), over a large area at high deposition rate as compared to other coating

processes such aselectroplating, physical and chemical vapor deposition. Coating materials available for thermal spraying include metals,alloys, ceramics, plastics and composites. They are fed in powder or wire form, heated to a molten or semimolten state and accelerated towards substrates in the form of micrometer-size particles.

Combustion or electrical arc discharge is usually used as the source of energy for thermal spraying. Resulting coatings are made by the accumulation of numerous sprayed particles. The surface may not heat up significantly, allowing the coating of flammable substances.

Coating quality is usually assessed by measuring its porosity, oxide content, macro and micro-hardness, bond strength andsurface roughness. Generally, the coating quality increases with increasing particle velocities.

Several variations of thermal spraying are distinguished:

Plasma spraying

Detonation spraying

Wire arc spraying

Flame spraying

High velocity oxy-fuel coating spraying (HVOF)

Warm spraying

Cold spraying

| Product | Chemical Composition | Available Sizes | Comparable Products | Hardness and Bond Strength | Typical Characteristics and Applications | |

| Name | ||||||

| NiAl95/5 | Nickel Aluminum | 1.6mm, 2.0mm | Tafa 75B Bond Arc® | 78 Rb | High temperature resistance | |

| Bond Arc® | Metco 8400 | 9746 PSI | Oxidation and abrasion resistant | |||

| Ni 5Al | Metco 450 | Dense coatings | ||||

| NiCr80/20 | Nickel Chrome | 1.6mm, 2.0mm | Tafa 06C | 90 Rb | Machinable | |

| Ni 80 Cr 20 | Praxair 80/20 | 7324 PSI | Heat Oxidation Resistance | |||

| Metco Nickel #33 | Oxygen barrier under ceramic coatings | |||||

| Monel 400 | Monel | 1.6mm, 2.0mm | Tafa 70T | 80-84 Rb | Marine corrosion protection | |

| Ni 27 Cu 2.0Fe 1.5Mg | Praxair Monel | 4307 PSI | Print rolls | |||

| Metco Monel | ||||||

| NiAl80/20 | Nickel Aluminum | 1.6mm, 2.0mm, 3.17mm |

Tafa 79B | 55-80 Rb | High temperature resistance | |

| Ni 20Al | Metco 405-1 | Oxidation and abrasion resistant | ||||

| Metco 405, 405NS | 8949 PSI | Dense coatings | ||||

Our company use Vaccum furnace and casting control to mak the NiAl alloy solid wire, it is specially used for arc spray boning layer. This wire has stable chemical composition, low oxgen and high bonding strength.

| Chemical Composition | Coating Strength (Mpa) |

Melting temp (c) |

Coating Hardness (HRC) |

| Ni 95% Al 5% | 65-68 | 1010 |

23-25 |

Applying technique: Arc spray

Specification of wire: 1.6mm, 2.0mm, 15kg/spool

NiAl20 is a cored wire specifically designed for either arc spraying or flame spraying. It is self-bonding to most materials and requires minimal surface spreparation. Bond strengths in excess of 9000 psi

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Contact Person: Mr. Qiu

Tel: +8613795230939

-

Thermal Spraying Aluminum Wire

-

Zn85Al15 Thermal Spray Wire

-

Solid Ni95Al5 Thermal Spray Wire 1.6mm / 2mm High Performance With ISO / CE

-

Machine Element Restoration Monel 400 Wire Good Corrosion Resistance

-

Hastelloy C276 TIG MIG Welding Wire, AWS A5.14 ERNiCrMo-4, UNS 2.4819, for Corrosion Resistance

-

HCF-45 (45CT) Thermal Spray Wire High Carbon Chromium