|

|

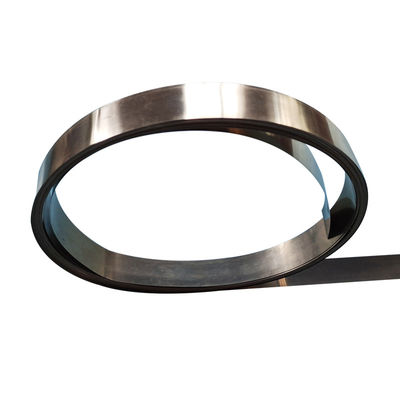

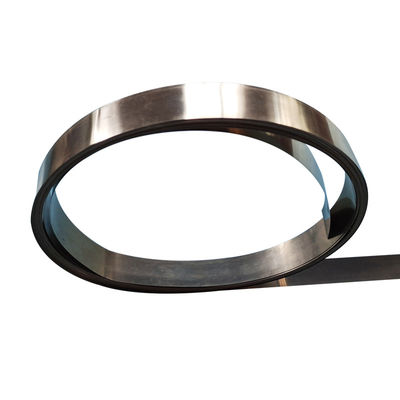

Bright Smooth Stainless Steel SUS 632 Wire Strip 05Cr17Ni4Cu4Nb

|

Product Details:

Payment & Shipping Terms:

|

| Application: | Aerospace Component | Shape: | Sheet |

|---|---|---|---|

| Surface: | Bright &smooth | Color: | Silvery White |

| Feature: | High Efficiency | Standard: | ASTM,DIN |

| Density: | 7.75g/cm3 | ||

| Highlight: | Aerospace Smooth Stainless Steel Strip,632 Stainless Steel Wire Strip,Bright Stainless Steel Wire Strip |

||

PH stainless Steel 05Cr17Ni4Cu4Nb SUS 632 wire, SUS 632 strip supplied

SUS630 Martensitic Stainless Steel

Chinese Grade: 0Cr17Ni4Cu4Nb

(UNS S17400, AISI 630, AMS5643, ASTM A705, ASTM A564)

SUS630(Japanese Grade)is martensitic precipitation hardening stainless steel. It has high strength, high hardness, good welding performance and corrosion resistance. It has been widely used in valve,shaft,chemical fiber industry and high strength parts with certain corrosion resistance requirements.

|

Country |

China |

America |

Japan |

Europe |

|

Grade |

0Cr17Ni4Cu4Nb |

ASTMS17400 |

SUS630 |

X5CrNiCuNb16-4 |

Characteristice and Usage

a) Precipitation hardening stainless steel with copper is used for manufacturing parts with high corrosion resistance and high strength, such as bearings and steam turbine parts.

b) Precipitation hardening martensitic stainless steel with copper and niobium has low carbon content, its corrosion resistance and weldability is better than that of common martensitic stainless steel. Similar to type18-8 stainless steel, its heat treatment process is simple and the machinability is good, but it is difficult to meet the cryogenic processing.

Metallographic Structure: precipitation hardening type

Application Industry: offshore platform, helideck, other platforms, food industry, pulp and paper industry, aerospace (turbine blade), mechanical parts and nuclear waste barrel

Chemical Compostion%

|

GRADE |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Cu |

Nb |

|

0Cr17Ni4Cu4Nb |

≤0.07 |

≤1.00 |

≤1.00 |

≤0.04 |

≤0.030 |

3.0-5.0 |

15.5-17.5 |

- |

3.0-5.0 |

0.15-0.45 |

|

ASTMS17400 |

≤0.07 |

≤1.00 |

≤1.00 |

≤0.04 |

≤0.030 |

3.0-5.0 |

15.5-17.5 |

- |

3.0-5.0 |

0.15-0.45 |

|

SUS630 |

≤0.07 |

≤1.00 |

≤1.00 |

≤0.04 |

≤0.030 |

3.0-5.0 |

15.5-17.5 |

- |

3.0-5.0 |

0.15-0.45 |

|

X5CrNiCuNb16-4 |

≤0.08 |

≤1.00 |

≤1.00 |

≤0.045 |

≤0.030 |

3.0-5.0 |

15.0-17.0 |

- |

3.0-5.0 |

0.15-0.45 |

Mechanical Property

|

Aging Temperature |

480℃ |

550℃ |

580℃ |

620℃ |

|

Tensile Strength σb (MPa) |

≥1310 |

≥1060 |

≥1000 |

≥930 |

|

Yieldσ0.2 (MPa) |

≥1180 |

≥1000 |

≥865 |

725 |

|

Elongationδ5 (%) |

≥10 |

≥12 |

≥13 |

≥16 |

|

Section Shrinkageψ (%) |

≥40 |

≥45 |

≥45 |

≥50 |

|

Hardness |

≥375HB/≥40HRC |

≥331HB/≥35HRC |

≥302HB/≥31HRC |

≥277HB/≥28HRC |

Heat Treatment

SUS630 alloy is precipitated, Quenched and martensitic stainless steel with high strength, hardness and corrosion resistance. However, its mechanical properties which can reach the compressive strength of 1100-1300 MPa (160-190 Ksi) will be more perfect through heat treatment.

This grade cannot be used at temperatures higher than 300 ℃ (570F) or at very low temperature. Its corrosion resistance is the same as that of 304 and 430 in normal atmosphere, diluted acid or salt.

![]()

![]()

![]()

FAQ

1. What's the minimum quantity customer can order?

If we have your size in stock, we can provide any quantity you want.

If we do not have, for spool wire, we can produce 1 spool, about 2-3kg. For coil wire, 25kg.

2. How can you pay for small sample amount?

We have account, wire transfer for sample amount also ok.

3. Customer do not have express account. How will us arrange the delivery for sample order?

Just need to provide your address information, we will check the express cost, you can arrange the express cost together with sample value.

4. What's our payment terms?

We can accept LC T/T payment terms, it also depending on delivery and total amount. Let's talk more in details after getting your detailed requirements.

5. Do you provide free samples?

If you want several meters and we have stock of your size, we can provide, customer need to bear the International express cost.

6. What's our working time?

We will give you reply through email/phone Online contact tool within 24 hours. No matter working day or holidays.

Contact Person: Mr. Qiu

Tel: +8613795230939

-

19 Strands Heating Nichrome Wire Alloy

-

Ni80 AWG38 Bright Soft Nichrome Resistance Wire For Electronic Cigarette

-

HRE Ferro Chromium Aluminium Heating Element Flat Wire

-

Cr20Ni30 NiCr3020 Nichrome Alloy , Nichrome Resistance Wire / Ribbon

-

ROHS Nichrome Alloy 19 Strands 60/61 Nickel Chrome Wire For PWHT Ceramic Heater Pads

-

37*0.38mm Stranded Ni80Cr20 Heating Wire | 23.6 Ω/m | Extreme Flex Robotics Heaters | AMS 2275 | 500k+ Cycles