|

|

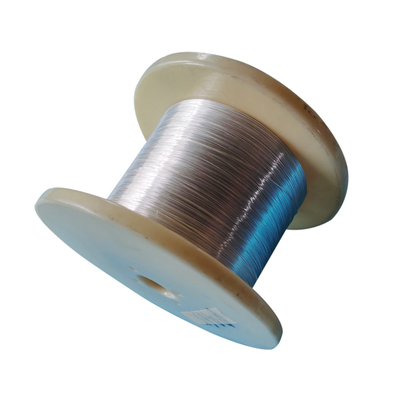

SWG18 Swg19 Ni30Cr20 Wire Nickel Chrome 30/20 Heating Wire For Walking Beam Furnace

|

Product Details:

Payment & Shipping Terms:

|

| Resistivity: | 1.04μΩ.m | Shape: | Tape |

|---|---|---|---|

| Surface: | Bright And Annealed | Application: | Element |

| Tensile Strength: | 675 | Enamelled: | Available |

| Elongation: | 35 | ||

| Highlight: | Nickel Chrome 30/20 Heating Wire,Nickel Chrome Ni30Cr20 Wire,Walking Beam Furnace Nickel Chrome Wire |

||

SWG18 swg19 Ni30Cr20 wire nickel chrome 30/20 heating wire for walking beam furnace

OhmAlloy104B

(Common Name:Ni30Cr20,Nikrothal 30, N3, HAI-NiCr 30, Resistohm 30,30-20 Ni-Cr,Nikrothal 3.)

OhmAlloy104B is a nickel-chromium alloy (NiCr alloy) characterized by High resistivity, good oxidation resistance,very good form stability,good ductility and excellent weldability. It is suitable for use at temperatures up to 1100°C.

Typical applications for OhmAlloy104B are used in olid hot plates,open coil heaters in HVAC systems,night-storage heaters,convection heaters,heavy duty rheostats and fan heaters. And also used for heating cables and rope heaters in defrosting and de-icing elements,electric blankets and pads, car seats,baseboard heaters,floor heaters and resistors.

ichrome Grade: Ni70Cr30,Ni80Cr20, Ni60Cr15, Ni35Cr20, Ni30Cr20

Description:

Ni30Cr20 is a nickel-chromium alloy (NiCr alloy) for use at temperatures up to 1200°C (2190°F). The alloy is characterized by high resistivity, good oxidation resistance and very good form stability. It has good ductility after use and excellent weldability.

Ni30Cr20 is used for making electric heating elements in home appliances and industrial furnaces. Typical applications are flat irons, ironing machines, water heaters, plastic moulding dies, soldering irons, metal sheathed tubular elements and cartridge elements.

Chemical Composition & Property:

| Properties | Grade | |

| Ni30Cr20 | ||

| Chemical composition % | Ni | 30.0~34.0 |

| Cr | 18.0~21.0 | |

| Fe | Balance | |

| Highest service temperature °C | 1100 | |

| Melting point °C | 1390 | |

| Density g/cm3 | 7.90 | |

| Resistivity μΩ.m,20°C | 1.04 | |

| Elongation % | ≥20 | |

| Specific heat J/g.°C | 0.500 | |

| Thermal conductivity KJ/m.h.°C | 43.8 | |

| Coefficient of linear extensibility α×10-6/°C | 19.0 | |

| Microstructure | Austenite | |

| Magnetic property | nonmagnetic | |

![]()

Normal composition%

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Other |

| Max | |||||||||

| 0.08 | 0.02 | 0.015 | 1.00 | 1.0~2.0 | 18.0~21.0 | 30.0~34.0 | - | Bal. | - |

Typical Mechanical properties(1.0mm)

| Yield strength | Tensile Strength | Elongation |

| Mpa | Mpa | % |

| 340 | 675 | 35 |

Typical Physical properties

| Density (g/cm3) | 7.9 |

| Electrical resistivity at 20℃(Ωmm2/m) | 1.04 |

| Conductivity coefficient at 20℃ (WmK) | 13 |

| Coefficient of thermal expansion | |

| Temperature | Coefficient of Thermal Expansion x10-6/℃ |

| 20 ℃- 1000℃ | 19 |

| Specific heat capacity | |

| Temperature | 20℃ |

| J/gK | 0.50 |

| Melting point (℃) | 1390 |

| Max continuous operating temperature in air (℃) | 1100 |

| Magnetic properties | non-magnetic |

Temperature Factors Of Electrical Resistivity

| 20℃ | 100℃ | 200℃ | 300℃ | 400℃ | 500℃ | 600℃ |

| 1 | 1.023 | 1.052 | 1.079 | 1.103 | 1.125 | 1.141 |

| 700℃ | 800℃ | 900℃ | 1000℃ | 1100℃ | 1200℃ | 1300℃ |

| 1.158 | 1.173 | 1.187 | 1.201 | 1.214 | 1.226 | - |

Style of supply

| Alloys Name | Type | Dimension | ||

| OhmAlloy104BW | Wire | D=0.03mm~8mm | ||

| OhmAlloy104BR | Ribbon | W=0.4~40 | T=0.03~2.9mm | |

| OhmAlloy104BS | Strip | W=8~250mm | T=0.1~3.0 | |

| OhmAlloy104BF | Foil | W=6~120mm | T=0.003~0.1 | |

| OhmAlloy104BB | Bar | Dia=8~100mm | L=50~1000 | |

Contact Person: Mr. Qiu

Tel: +8613795230939

-

19 Strands Heating Nichrome Wire Alloy

-

Ni80 AWG38 Bright Soft Nichrome Resistance Wire For Electronic Cigarette

-

HRE Ferro Chromium Aluminium Heating Element Flat Wire

-

Cr20Ni30 NiCr3020 Nichrome Alloy , Nichrome Resistance Wire / Ribbon

-

ROHS Nichrome Alloy 19 Strands 60/61 Nickel Chrome Wire For PWHT Ceramic Heater Pads

-

37*0.38mm Stranded Ni80Cr20 Heating Wire | 23.6 Ω/m | Extreme Flex Robotics Heaters | AMS 2275 | 500k+ Cycles