|

|

ASTM 19400 Foil In Thickness 0.2mm To 1.0mm

|

Product Details:

Payment & Shipping Terms:

|

| Type: | Strip | Thickness: | 0.2 |

|---|---|---|---|

| Application: | Industry | Material: | Copper / Copper Alloy |

| Shape: | Wire | Resistance (μω.m): | Stable |

| Welding Current: | International Standard | ||

| Highlight: | 1.0mm ASTM 19400 foil,0.2mm ASTM 19400 foil,ASTM 19400 foil |

||

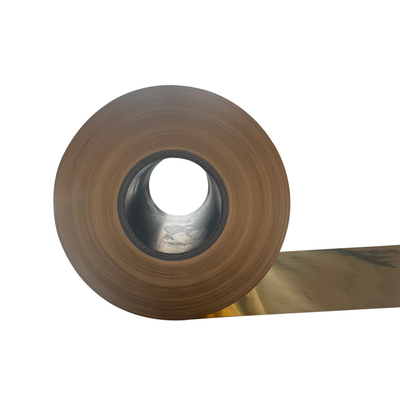

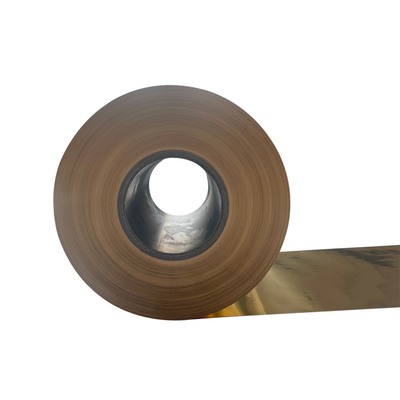

ASTM 19400 foil in thickness 0.2mm to 1.0mm

The remarkable characteristics of the material are: high strength, high conductivity, high precision and high softening temperature resistance, as well as suitable processing properties and electroplating brazing properties.

It is mainly used for the production of semiconductor chip lead frame, integrated circuit and electronic discrete devices, electronic industry connectors, etc.

Standard:

| GB/T | DIN | EN | ASTM | JIS |

| QFe2.5 |

CuFe2P 2.1310 |

CuFe2P CW107C |

C19400 | C19400 |

Chemical composition:

| Cu | Bal. |

| Fe | 2.1-2.6 |

| Zn | 0.05-0.2 |

| P | 0.015-0.15 |

Physical property:

| Density(g/cm3) | 8.9 |

| Conductivity IACS% {(20℃)} | 60min |

| Modulus of elasticity(KN/mm2) | 121 |

| Thermal conductivity {W/(m*K)} | 280 |

|

Coefficient of thermal expansion (10-6/℃ 20/℃ ~100/℃) |

17.7 |

| Status | Tensile strength | Yield strength | Elongation A50 | Hardness | Bending test | |

| 90°(R/T) | ||||||

| (Rm,MPa) | (Rp0.2,MPa) | (%) | (HV) | GW | BW | |

| R300 | 300-340 | 240max | 20min | 80-100 | 0 | 0 |

| R340 | 340-390 | 240min | 10min | 100-120 | 0 | 0 |

| R370 | 370-430 | 330min | 6min | 120-140 | 0 | 0 |

| R420 | 420-480 | 380min | 3min | 130-150 | 0.5 | 0.5 |

| R470 | 470-530 | 440min | 4min | 140-160 | 0.5 | 0.5 |

| R530 | 530-570 | 470min | 5min | 150-170 | 1 |

1 |

![]()

![]()

Package

![]()

![]()

Contact Person: Mr. Qiu

Tel: +8613795230939

-

Manganin Strip Copper Based Alloys

-

MYFE-4/200 Polyimide Film Wrapped Insulated Copper Round Wire

-

Nickel Silver Strip / CuNi18Zn20 / C75200 / CW409J / NS106 For Decoration

-

CuNi40 Constantan Copper Based Alloys 25% Elongation High Resistance Wire

-

Low Voltage Copper Alloys Constantan Ribbon / Flat Wire 8.9 g / cm3 Density

-

0.05-2.0mm CuNi10 Strip | Stable Resistivity | Instrumentation Resistors | Low Temperature Coefficient | ROHS