|

|

Boiler Tubes SS 316 wire HRB 90-95 Typical Hardness 70% Deposit Efficiency

|

Product Details:

Payment & Shipping Terms:

|

| Material: | SS316 | Diameter: | 1.6mm,2.0mm |

|---|---|---|---|

| Package: | 15kg/spool | Application: | Boiler Tubes |

| Spraying Way: | Arc Spraying | Typical Hardness: | HRB 90-95 |

| Bond Strength: | 6750 Psi | Deposit Efficiency: | 70% |

| Highlight: | Metal Wire,SS 316 wire |

||

Boiler Tubes SS 316 wire HRB 90-95 Typical Hardness 70% Deposit Efficiency

PRODUCT OVERVIEW

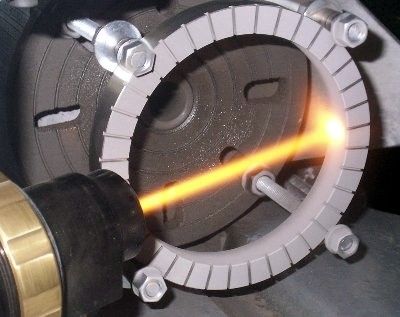

SS316 is a 316 stainless steel wire specifically designed for arc spraying. It produces a dense, well-bonded coating with excellent machinability and wear and corrosion resistance. SS316 is widely used for machine element repair, dimensional restoration and wear resistance applications. It has high shrink characteristics and should not be used for coatings over 0.075 inches thick.

TYPICAL DEPOSIT CHARACTERISTICS:

Þ Typical Hardness: HRB 90-95

Þ Bond Strength: 6750 psi

Þ Deposit Rate: 10 lbs/hr/100A

Þ Deposit Efficiency 75%

Þ Wire Coverage: 0.8 oz/ft2 / mil

Þ Surface Texture * Variable

Þ Machinability Good

* Depends on air pressure used

SURFACE PREPARATION

Surface should be clean, white metal, with no oxides (rust), dirt, grease, or oil on the surface to be coated. Note: It is best not to handle surfaces after cleaning.

Recommended method of preparation is to grit blast with 24 mesh aluminum oxide, rough grind, or rough machine in a lathe.

APPLICATION

Þ Parts Restoration

Þ Rams

Þ Food Industry Rolls

SPECIFICATION

316 SS

NOMINAL CHEMICAL COMPOSITION (wt%)

| Cr | Ni | Mn | Si | Fe | Mo |

| 17.0 | 12.0 | 2.0 | 1.0 | Bal | 2.5 |

RECOMMENDED SPRAY PARAMETERS:

| Diameter | Air Pressure | Voltage | Amperage | Standoff |

| 1/16” (1.6mm) | *50-60 psi | *28-30 | *100-200 | *4-6 in (10-15 cm) |

* Parameters are typical and may vary depending on equipment used. Contact your equipment manufacturer for optimum spray parameters

STANDARD SIZES & PACKAGING:

| Diameter | Packaging |

| 1/16” (1.6mm) | 15kg/spool |

![]()

Contact Person: Mr. Qiu

Tel: +8613795230939

-

Thermal Spraying Aluminum Wire

-

Zn85Al15 Thermal Spray Wire

-

Solid Ni95Al5 Thermal Spray Wire 1.6mm / 2mm High Performance With ISO / CE

-

Machine Element Restoration Monel 400 Wire Good Corrosion Resistance

-

Hastelloy C276 TIG MIG Welding Wire, AWS A5.14 ERNiCrMo-4, UNS 2.4819, for Corrosion Resistance

-

HCF-45 (45CT) Thermal Spray Wire High Carbon Chromium